Production of CLT panels are done in modern facilities, the elements are exclusively produced in a project-related way. The thickness of the elements and the number of plies used mostly depends on the structural and fire-protection requirements. On the basis of approved production plans, the elements are cut using state-of-the-art CNC systems. The elements are delivered directly to the construction site on a just-in-time basis, by a container. On location, they are mounted using a construction crane.

The crossways arrangement of the longitudinal and crosswise laminates reduces the swelling and shrinkage in the board plane to an insignificant minimum and static strength and shape retention increase considerably. Only exclusively technically seasoned timber with a wood moisture content of 12% (+/-2%) is used. Any timber laminates are subjected to quality control before their use.

Only VOC-free and formaldehyde-free PUR adhesives are used. The adhesives have been approved for the production of load-bearing timber components.

The adhesive is applied automatically over the entire surface approx. 0.15 kg/m² per joint. The laminated pressure at 0.6 N/mm² used during the manufacture of solid timber panels is 6 times higher when compared with vacuum press technology. The quality of the lamination of CLT is therefore of high quality and the load-bearing capacity comparatively higher.

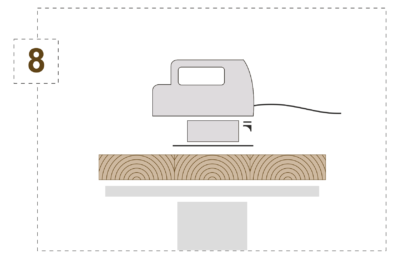

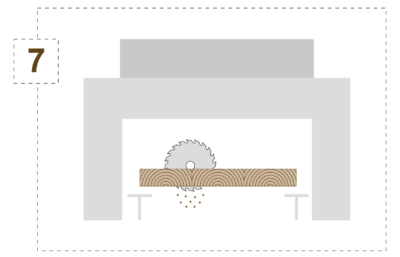

Factory cutting or beaming takes place using state-of-the-art CNC-technology. The basis for that form the production and cutting plans released by the client or the executing company, respectively.

• Format cut

• Window and door openings

• Recesses

• Rebates, jaggings and milled cut-outs for the element joint

• Bevel cuts

• Round cuts, round milling

• Drill holes

• Milled cut-outs for electrical installations

• Cut-outs for ceiling beams

• Special timber framing

The cut-to-size solid cross-laminated timber elements are delivered to the construction site just in time, and there they are assembled by expert timber construction companies or construction companies using a building crane within the shortest possible construction period. The connection of tradition, well-founded craftsmanship and state-of-the-art timber construction technology enables individual, stable-value constructing with particular attention being attached to the environment and energy consumption.

We are offering various lifting systems, depending on the panel type, panel size and surface quality. All lifting systems installed in the factory.